Overview

This case study is in progress. We are sharing results as of December 2023, nine years into a longer-term study, to inform foresters and other resource professionals about our ongoing work.

Central Mesic Hardwood Forest - Eastern (MHc36) is an excellent native plant community class to maintain oak canopy dominance. However, land managers have noted that mature oak-dominated MHc36 forests have an abundance of shade tolerant seedlings, saplings, and some pole-sized trees and very little oak regeneration. Based on natural succession patterns, it would be ideal to begin the process of regenerating oak in younger stands. However, we currently have large acreages of mature oak forests in need of regenerating but with inadequate oak advance regeneration. Therefore, our main goal is test treatments for regenerating northern red oak in mature forests where it is currently dominating the overstory but lacking in the understory. Additionally, and in doing so, we will compare the benefits to the costs of the treatments.

This case study compares various shelterwood silvicultural systems with varying site preparation and competition control treatments intended to develop vigorous oak advanced regeneration. Over time, we plan to continue measuring the degree to which various treatments affect oak regeneration success and recruitment, ecological integrity, wildlife habitat, future forest products, and cost-effectiveness.

Silviculture Objective(s)

Establish oak regeneration utilizing several different silvicultural strategies.

Short term goal (10 years):

Monitor regeneration success, competition density, plant community characteristics, wildlife habitat characteristics, and costs of each treatment in order to compare the efficacy of the following prescriptions at regenerating oak:

- Reserve shelterwood (two-aged) harvest - no understory treatment, natural regeneration only.

- Shelterwood harvest (even-aged) - no understory treatment, natural regeneration only.

- Shelterwood harvest (even-aged) - herbicide and mechanical site preparation, natural regeneration.

- Shelterwood harvest (even-aged) - herbicide site preparation, planted oak seedlings and natural regeneration.

- Shelterwood harvest (even-aged) - prescribed burn, planted oak seedlings and natural regeneration.

- Shelterwood harvest (even-aged) – prescribed burn, natural regeneration only.

- Reserve shelterwood (two-aged) - prescribed burn, natural regeneration only.

Longer term goal (10-100+ yrs.):

Continue to compare the treatment success on oak and other tree species recruitment into the forest canopy through monitoring the forest composition and structure and costs associated with final canopy removal (even-age system) vs. no final canopy removal (two-aged system). We are open to additional monitoring of specific wildlife habitat characteristics in the future if specific monitoring goals and protocols are identified and achievable with available resources.

Pre-treatment stand description and condition

Stand establishment and management history:

Northern red oak dominated canopy with sugar maple understory and sub-canopy.

Pre-treatment species composition:

The canopy was dominated by approximately 80-year-old red oak (~17 cords/acre) with components of black ash, big-tooth aspen, trembling aspen, paper birch, basswood, sugar maple, and red maple. Competing stems of hazel, ironwood, etc. stem density is low to moderate. Advanced regeneration was heavily dominated by sugar maple (1 to 8 inches DBH).

Pre-treatment growth and stocking:

Stand basal area was 135-140 ft2/ac with 20 to 33 total cords/acre of merchantable timber volume.

Pre-treatment forest health issues:

None noted.

Landowner objectives/situation:

While specific objectives vary from parcel to parcel, forest lands under the administration of DNR-Wildlife are managed in alignment with Section Forest Resource Management Plans (SFRMP) to ensure that forest management activities meet statewide goals for wildlife habitat, ecological protection, timber production, and cultural/recreational values. The DNR assembles teams from the Divisions of Forestry, Fish & Wildlife, and Ecological & Water Resources who work with partners and the public to develop SFRMPs.

Specific objectives for this project included improving wildlife habitat, outdoor recreation opportunities and production of forest products.

The MNDNR goal for oak forest acreage in this area at the time of project initiation was to maintain it through regeneration of mature stands.

Silviculture Prescription

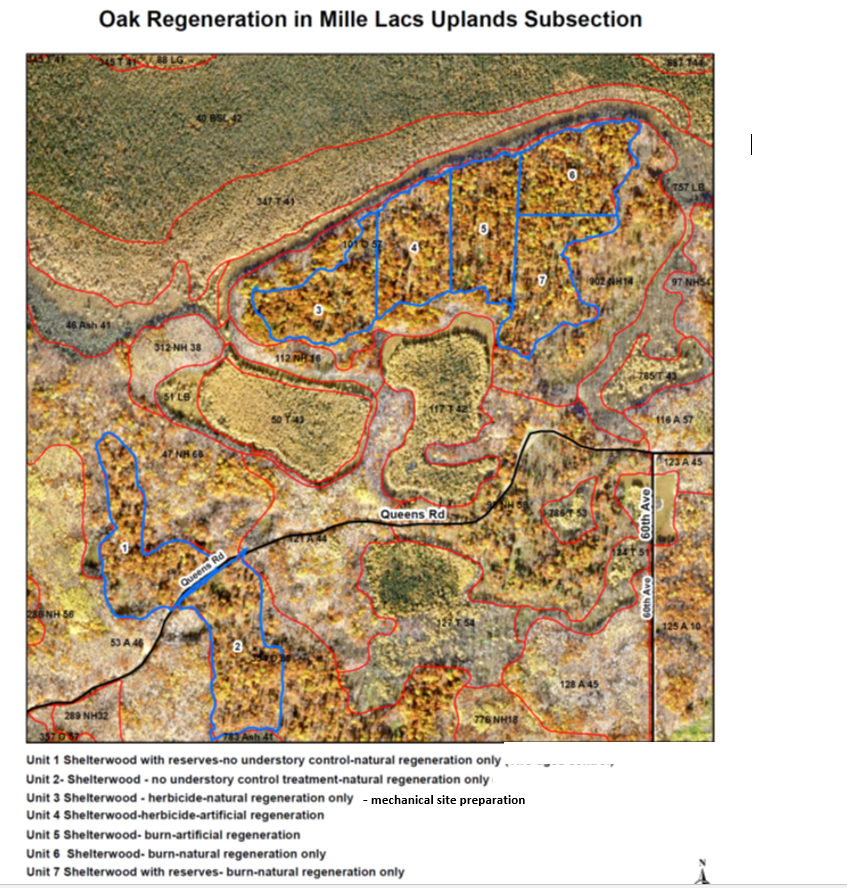

See Figure 1 for a map of the layout of the 7 treatment units.

Figure 1: map of the layout of the 7 treatment units.

Initial Shelterwood Harvest on all Seven Units

An initial or establishment shelterwood harvest was conducted on all 7 sites from January to March of 2013. Approximately 80 ft2 basal area of (mostly oak) trees were left unharvested as overwood, with a target post-harvest crown closure of 60%. Harvest of all non-reserved timber over 4" dbh except butternut, hickory, cherry or conifers and all green painted reserve trees.

Site 1: Reserve shelterwood (two-aged) - no understory treatment, natural regeneration only. 12.7 acres

The original plan was for a final removal of the overstory (with 10-12 reserve trees per acre left) after adequate establishment of advance oak regeneration. However, due to habitat concerns for a rare species, the final harvest removal either won’t occur at all, or else the number of reserves trees will have to be higher than originally planned by retaining at least 80% of original basal area.

Site 2: Two-step shelterwood (even-aged) - no understory treatment, natural regeneration only. 12.7 acres.

Date TBD: Final harvest with reserves after establishment of adequate advance regeneration

Site 3: Two-step shelterwood (even-aged) - herbicide and mechanical site preparation, natural regeneration. 10.7 acres.

August 2014: Broadcast chemical site preparation using herbicides Roundup & Triclopyr.

September 2014: Mechanical raking site preparation.

Site 4: Two-step shelterwood (even-aged) - herbicide site preparation, planted oak seedlings and natural regeneration. 11 acres.

August 2014: Broadcast chemical site preparation using herbicides Roundup & Triclopyr.

May 2015: Hand underplant northern red oak at 498 stems/acre.

Fall 2015: Bud cap protection on northern red oak seedlings. Cost: $40/acre.

Fall 2016: Bud cap protection on northern red oak seedlings.

Site 5: Two-step shelterwood (even-aged) - prescribed burn, planted oak seedlings and natural regeneration. 11.5 acres.

Fall 2015: Prescribed burn. The main objective of the burn was to suppress competing vegetation of especially hazel and ironwood. Staff involved in the burn reported moderate success in suppression of brush. A second objective was to assess impact of burning on stimulating growth of natural oak seedings.

Spring 2016: Hand underplant northern red oak seedlings at 520 stems/acre.

Fall 2016: Bud cap protection on northern red oak seedlings. Cost: $35/acre.

Spring 2018: Prescribed burn. The main objective of the burn was to suppress competing vegetation of especially hazel and ironwood. A second objective was to assess impact of burning on stimulating growth of planted and natural oak seedings.

Site 6: Two-step shelterwood (even-aged) – prescribed burn, natural regeneration only. 11.6 acres.

Fall 2015: Prescribed burn. The main objective of the burn was to suppress competing vegetation of especially hazel and ironwood. Staff involved in the burn reported moderate success in suppression of brush. A second objective was to assess impact of burning on stimulating growth of natural oak seedings.

Spring 2018: Prescribed burn. The main objective of the burn was to suppress competing vegetation of especially hazel and ironwood. Staff involved in the burn reported moderate success in suppression of brush. A second objective was to assess impact of burning on stimulating growth of natural oak seedings.

Site 7: Reserve shelterwood (two-aged) - prescribed burn, natural regeneration only. 11.6 acres.

Fall 2015: Prescribed burn. The main objective of the burn was to suppress competing vegetation of especially hazel and ironwood. Staff involved in the burn reported moderate success in suppression of brush. A second objective was to assess impact of burning on stimulating growth of natural oak seedings.

Spring 2018: Prescribed burn. The main objective of the burn was to suppress competing vegetation of especially hazel and ironwood. A second objective was to assess impact of burning on stimulating growth of planted and natural oak seedings.

What actually happened during the treatment

For the most part, prescriptions were implemented as planned with a few exceptions.

A rare species was found in the vicinity of one of the sites after the initial harvest, so the prescription was adjusted to avoid negative impacts per guidance for the rare species. Had we discovered this sooner, the initial prescription would have been adjusted or different. Monitoring of the rare species population is on-going.

Deer exclusion fencing was originally planned for the planted sites (4 and 5). The fencing was not installed because of access concerns for construction equipment and staffing resource concerns for maintenance.

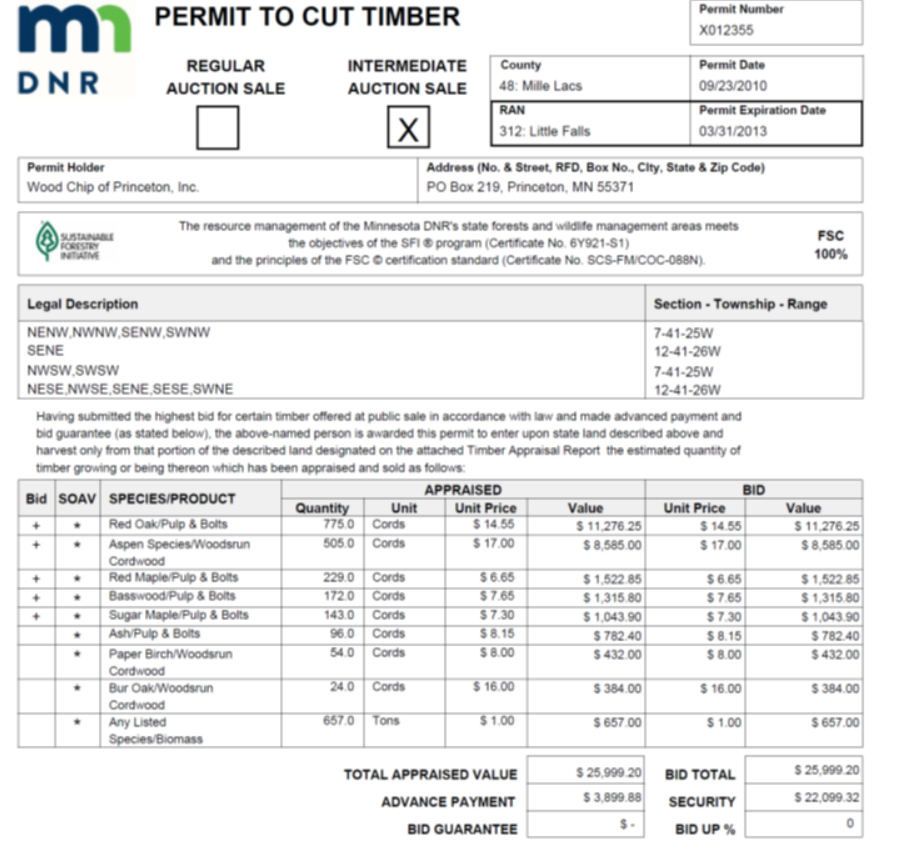

Figure 2: Page 1 of 2010 timber permit for all 7 treatment units.

Post-treatment assessment

Advance Oak Regeneration

One major question we wanted to answer with this study was which treatment(s) worked best to produce advance oak regeneration of adequate size (> 4’ high) and stocking (> 60%) to ensure a desired oak component in the future stand.

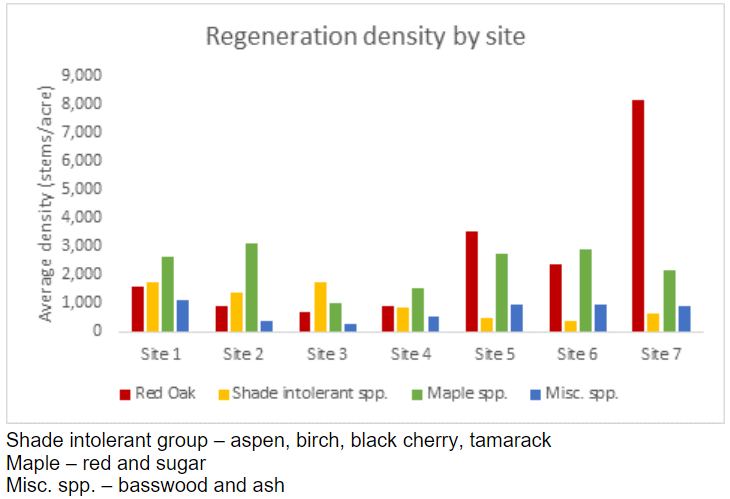

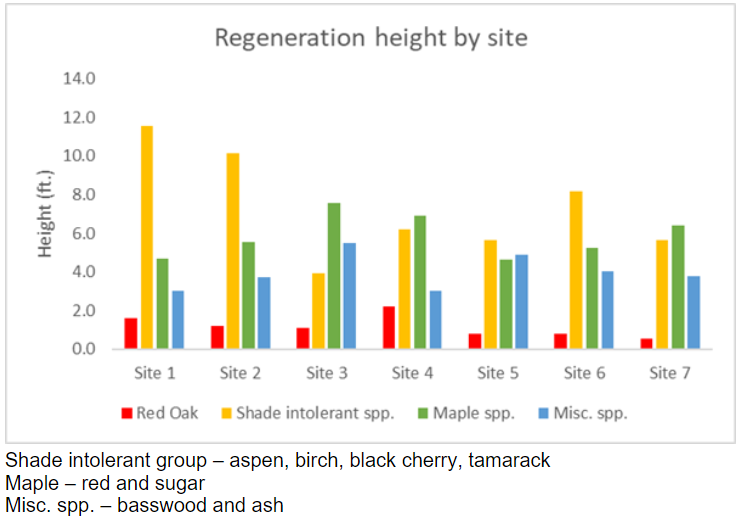

As of 2021, it appears that there is not yet sufficient advance oak regeneration to proceed with a final shelterwood harvest. As shown in Table 1, Table 2, Figure 3 and Figure 4, the number and distribution of oak seedlings on all sites is good (stocking 100% for all treatments), but the large majority of them are still quite small.

Table 1: Red oak regeneration summary by site in October 2021. Cost per stem of red oak analysis included to demonstrate cost per red oak stem >1’ in height in 2023.

Note: All sites had a first-stage shelterwood harvest in 2013. Harvest of all timber over 4" dbh except Butternut, Hickory, Cherry or Conifers and all green painted reserve trees. Approximately 80 ft2 basal area of reserve (mostly oak) trees were left unharvested, with a target post-harvest crown closure or 60%. Last column of table added after 2023 regeneration survey. Cost per stem of red oak over 1’ height was calculated after weighting stems per acre by percent of site stocked.

Site | Treatment | Red oak regen density (stems/ac) | Stocking (%) | Avg. height of red oak (ft) | Max. height of red oak (ft) | Cost of all treatments (per acre) | Cost per red oak stem > 1’ ht. |

1 | Understory control (no treatment; nat regen only) | 1583 | 100 | 1.6 | 15 | $0 | $0.23 |

2 | Understory control (no treatment; nat regen only) | 883 | 100 | 1.2 | 2 | $0 | $0.23 |

3 | Herbicide and mechanical site prep; nat regen only | 683 | 100 | 1.1 | 4 | $320 | $2.45 |

4 | Herbicide site prep; planted oak seedlings | 915 | 100 | 2.2 | 4.5 | $527 | $1.52 |

5 | Prescribed burn; planted oak seedlings | 3567 | 100 | 0.8 | 1.5 | $629 | $0.52 |

6 | Prescribed burn; nat regen only | 2367 | 100 | 0.8 | 1.5 | $305 | $0.58 |

7 | Prescribed burn; nat regen only | 8183 | 100 | 0.6 | 0.7 | $305 | $0.58 |

Table 2: Fall 2021 trees/acre and average height by species for 7 treatment sites. Red oak stocking is at 100% for all sites.

| Site 1 Nat. regen/no understory control | Site 2 Nat. regen/no understory control | Site 3 Herbicide & mech. site prep, natural regen. | Site 4 Herbicide site prep., planted oak and natural regen. | Site 5 Prescribed burn, planted oak and natural regen. | Site 6 Prescribed burn, natural regen. only | Site 7 Prescribed burn, natural regen. only | |||||||

Crop Species | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) |

Red Oak | 1,583 | 1.6 | 883 | 1.2 | 683 | 1.1 | 915 | 2.2 | 3,567 | 0.8 | 2,367 | 0.8 | 8,183 | 0.6 |

Paper Birch | 683 | 13 | 317 | 9.0 | 1,483 | 4.0 | 600 | 7.3 | 333 | 6.5 | 117 | 5.0 | 250 | 3.5 |

Sugar Mple | 2,200 | 4.6 | 2,766 | 6.0 | 600 | 7.2 | 767 | 5.5 | 2,217 | 5.0 | 2,516 | 5.5 | 1,533 | 7.8 |

Red Mple | 433 | 4.2 | 366 | 2.0 | 417 | 4.8 | 784 | 4.1 | 533 | 2.5 | 384 | 2.1 | 633 | 2.1 |

Aspen | 1,050 | 10.8 | 1,066 | 10.5 | 0 | 0.0 | 0 | 0.0 | 133 | 3.5 | 283 | 9.5 | 400 | 7.0 |

Basswood | 150 | 3.1 | 67 | 2.5 | 0 | 0.0 | 0 | 0.0 | 67 | 3.5 | 217 | 5.2 | 150 | 5.2 |

Ash | 983 | 3.0 | 300 | 4.0 | 283 | 5.5 | 533 | 3.0 | 883 | 5.0 | 767 | 3.7 | 750 | 3.5 |

Black Chry | 17 | 2.0 | 0 | 0.0 | 50 | 5.0 | 0 | 0.0 | 0 | 0.0 | 0 | 0.0 | 0 | 0.0 |

Tamarack | 0 | 0.0 | 0 | 0.0 | 217 | 3.3 | 250 | 3.6 | 0 | 0.0 | 0 | 0.0 | 0 | 0.0 |

Total | 9,032 |

| 6,950 |

| 4,482 |

| 4,598 |

| 7,933 |

| 8,351 |

| 12,317 |

|

Table 3: Fall 2018 trees/acre and average height by species for 7 treatment sites. Red oak stocking: Sites 1,2,4,5,6 = 100%; Site 3: 60%; Site 7: 80%.

| Site 1 Nat. regen/no understory control | Site 2 Nat. regen/no understory control | Site 3 Herbicide & mech. site prep, natural regen. | Site 4 Herbicide site prep., planted oak and natural regen. | Site 5 Prescribed burn, planted oak and natural regen. | Site 6 Prescribed burn, natural regen. only | Site 7 Prescribed burn, natural regen. only | |||||||

Crop Species | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) |

Red Oak | 1,740 | 3 | 2,200 | 2.3 | 120 | 2.7 | 640 | 2.8 | 640 | 1.6 | 720 | 1.5 | 200 | 1.8 |

Paper Birch | 800 | 5 | 2,400 | 4.8 | 1,580 | 4.6 | 600 | 3.2 | 0 | 0 | 80 | 4 | 160 | 6 |

Sugar Maple | 6,960 | 6.2 | 4,920 | 6 | 1,440 | 3.6 | 460 | 3.4 | 3,740 | 2.2 | 1,940 | 2.4 | 1,040 | 2.2 |

Red Maple | 2,380 | 2.2 | 7,040 | 2.6 | 1,220 | 2.3 | 1,360 | 2.6 | 1,040 | 2.2 | 500 | 1.6 | 360 | 2.5 |

Tr. Aspen | 640 | 8.2 | 1,180 | 6.7 | 20 | 1 | 40 | 2.5 | 0 | 0 | 660 | 4.6 | 240 | 5 |

Basswood | 480 | 14 | 80 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 200 | 3 | 0 | 0 |

Ash | 1,220 | 5 | 1,260 | 2.3 | 280 | 2 | 40 | 1.5 | 780 | 3 | 540 | 2 | 140 | 2.6 |

Black Cherry | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

BT. Aspen | 0 | 0 | 760 | 12.5 | 60 | 2.5 | 20 | 7 | 400 | 3.2 | 0 | 0 | 0 | 0 |

Tamarack | 0 | 0 | 0 | 0 | 300 | 1 | 60 | 1.5 | 0 | 0 | 0 | 0 | 0 | 0 |

Bur Oak | 20 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Total | 14,240 |

| 19,840 |

| 5,020 |

| 3,220 |

| 6,600 |

| 4,640 |

| 2,140 |

|

Table 4: Fall 2017 trees/acre and average height by species for 7 treatment sites. Red oak stocking: Sites 3, 5 & 6: 100%, Site 1: 75%, Site 2: 88%, Site 4: 86%, Site 7: 0%

| Site 1 Nat. regen/no understory control | Site 2 Nat. regen/no understory control | Site 3 Herbicide & mech. site prep, natural regen. | Site 4 Herbicide site prep., planted oak and natural regen. | Site 5 Prescribed burn, planted oak and natural regen. | Site 6 Prescribed burn, natural regen. only | Site 7 Prescribed burn, natural regen. only | |||||||

Crop Species | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) | Trees/ Ac. | Avg. Ht. (ft) |

Red Oak | 1,525 | 3.2 | 1,225 | 2.5 | 860 | 2.4 | 829 | 1.5 | 1,057 | 2.6 | 1,283 | 1.8 | 0 | 0 |

Paper Birch | 100 | 9 | 425 | 7.5 | 1,460 | 4.3 | 71 | 1 | 243 | 5.8 | 50 | 4 | 233 | 5 |

Sugar Maple | 2075 | 4.8 | 1,463 | 5.7 | 80 | 3 | 557 | 3.3 | 1,571 | 3.4 | 1,517 | 2.2 | 1,117 | 4.2 |

Red Maple | 750 | 2.4 | 1,138 | 4.1 | 0 | 0 | 671 | 2.3 | 929 | 2.6 | 600 | 1.2 | 150 | 4 |

Aspen | 1,950 | 8.6 | 975 | 7.3 | 20 | 1 | 43 | 3 | 1,514 | 6.4 | 733 | 9.3 | 317 | 8 |

Basswood | 188 | 6 | 0 | 0 | 0 | 0 | 29 | 5 | 100 | 2.5 | 0 | 0 | 150 | 5 |

Ash | 438 | 4 | 238 | 3.5 | 80 | 1 | 186 | 2.5 | 543 | 3.4 | 483 | 2 | 350 | 2.7 |

Black Cherry | 88 | 4.8 | 75 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 67 | 4 | 0 | 0 |

Tamarack | 0 | 0 | 0 | 0 | 60 | 1 | 271 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

Bur Oak | 0 | 0 | 25 | 2 | 0 | 0 | 00 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

White Pine | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 57 | 0.5 | 0 | 0 | 0 | 0 |

Total | 7,114 |

| 5,564 |

| 2,560 |

| 2,657 |

| 6,014 |

| 4,733 |

| 2,317 |

|

Figure 3: Average stems per acre by species and treatment site in October 2021.

Figure 4: Average stem height by species and treatment site in October 2021.

Given that oak stocking on all sites is good (Table 5), average height is the most significant factor to consider at this point, since larger, established seedlings have greater potential to recruit into larger size classes. Average height for oak is greatest on site 4 (herbicide site preparation, planted and natural regeneration) at 2.2 feet. Another observation is that the oak seedling numbers are higher on sites treated with prescribed burns, but the seedlings are very small. This is probably because of their younger age relative to the other sites.

Table 5: Red oak stems per acre. maximum and average heights (feet) on sample plots in fall 2017, 2018, and 2021.

| 2017 | 2018 | 2021 | ||||||

Site # & Description | Trees/ Ac. | Max. Ht. (ft) | Avg. Ht. (ft.) | Trees/ Ac. | Max. Ht. (ft) | Avg. Ht. (ft.) | Trees/ Ac. | Max. Ht. (ft) | Avg. Ht. (ft.) |

Site 1 Nat. regen/no understory control | 1,525 | 6 | 3.2 | 1,740 | 6 | 3 | 1,583 | 15 | 1.6 |

Site 2 Nat. regen/no understory control | 1,225 | 3 | 2.5 | 2,200 | 3 | 2.3 | 883 | 2 | 1.2 |

Site 3. Herbicide & mech., nat. regen. | 860 | 4 | 2.4 | 120 | 6 | 2.7 | 683 | 1.5 | 1.1 |

Site 4. Herbicide, planted & nat. oak regen. | 829 | 2 | 1.5 | 640 | 8 | 2.8 | 915 | 4.5 | 2.2 |

Site 5 Prescribed burn, planted & nat. oak regen. | 640 | 2 | 2.6 | 640 | 2 | 1.6 | 3,567 | 1 | 0.8 |

Site 6 Prescribed burn, nat. regen. | 720 | 2 | 1.8 | 720 | 2 | 1.5 | 2,367 | 1.5 | 0.8 |

Site 7 Prescribed burn, nat. regen. | 0 | 0 | 0 | 200 | 4 | 1.8 | 8,183 | 0.7 | 0.6 |

From the data we have, and observations while collecting it, we feel there is not yet adequate advance oak regeneration over 4 feet in height on the sites to support a final harvest decision. An oak crop tree competition release is planned for the summer of 2022, using brush saws. This work is needed to enable adequate numbers of oak to grow above deer browse height and most vegetative competition.

We plan to gather regeneration data again in 2023 to enable a well-informed decision on timing of the final shelterwood harvest.

Vegetative Competition Control

Control of competing vegetation is critical for oaks to recruit into larger size classes. Sugar maple in particular can provide some of the most challenging competition.

As shown in Table 2, treatments 3 (herbicide and mechanical site preparation) and 4 (herbicide site preparation) reduced sugar maple numbers the best so far. While there are still quite a few sugar maple stems on these areas, they are noticeably less dense as of 2021 than on the other treatment areas. Average sugar maple/acre is 600 and 767 respectively for sites 3 and 4. All other treatments have average maple stems/acre over 1,500/acre, with most sites over 2,000/acre.

We were somewhat surprised to see high sugar maple/acre numbers on sites treated with prescribed burns. It is possible that in spite of best efforts, conditions resulted in burns that were just not intense enough to kill most maple stems. With its relatively thin bark, maple is susceptible to control by fire, but the fire still needs to be intense enough to do so. However, it is challenging to have conditions (fuel, temperature and humidity) to enable hot enough prescribed burns to consistently control maple competition.

A note on the importance of coppice origin oak: Many of the taller stems of oak regeneration were of coppice origin. Stump sprouts can be an important component of total oak regeneration because their rapid juvenile growth enables them to grow above competing vegetation and deer browse susceptibility faster than seedling origin stems.

Understory Plants

We gathered detailed baseline understory plant data in 2016 to enable assessment of treatment impacts to all plant species in the understory and overstory. We found plants to be consistent with those generally found in MHc36 plant communities.

We hope to gather similar data at future points in time and compare it to the baseline data to assess any impacts to understory plants.

Invasive Species

We observed some Canada thistle after herbicide treatment in sites 3 and 4. This is typically a short-term phenomenon, with the thistle becoming outcompeted by other vegetation in time.

We also observed low levels of reed canarygrass in some locations, which is common in this area, on these types of sites.

Figure 5: AFMP site 3 in summer 2021.

Figure 6: AFMP site 4 in summer 2021.

Figure 7: Forester Tim Stai surveys regeneration on the AFMP site in fall 2021

December 2023 Update

We gathered regeneration data in October of 2023 in order to provide an update to the original 2021 submission of this case study.

The October 2023 data was gathered after a brush saw crop tree release practice was completed in fall of 2022. The release work was done to enable adequate numbers of oak to recruit into larger size classes and grow above deer browse height and most vegetative competition before they are fully released by a final harvest removal of most of the remaining overstory trees. The goal is to achieve a strong oak component as the stand progresses to larger size classes over time. Note: Much of site 3 got inadvertently missed during the brushsaw release work. Therefore a 2024 brushsaw release may be done on site 3.

As of 2023, all units are on the way to becoming healthy central or northern hardwood stands, with anywhere from a fair to good oak component.

An important measure of oak regeneration adequacy before final harvest is the abundance and distribution of oak seedlings and saplings over 4 feet in height. Another important consideration is the abundance and distribution of oak seedlings in the 1 to 4 foot height class. At this point, stems of oak regeneration less than 1 foot in height are virtually irrelevant, since they are unable to compete with competing tree stems and other vegetation that has become established since the initial stage harvest in 2013.

While only 1 treatment (# 5 – two Rx burns and planting) has stocking of 4 foot-plus tall oak seedlings over 40% (Table 2023-1), all sites have stocking of 50% or more of oak seedlings over 1 foot tall. In fact, 4 treatments (#s 1&2 together, 4,5 and 6&7 together) have stocking of 63% or greater of oak seedlings over 1 foot tall (Figure 2023-2).

The two prescribed burn site preparation treatment (sites 5, 6 and 7) appears to have done the best job of facilitating oak regeneration establishment and recruitment above 1 foot tall so far. However, prescribed burning did not control competing stems of sugar maple nearly as well as herbicide and mechanical site prep. This means that the 2022 crop tree release work and expense was especially beneficial (even critical) for units other than the herbicide and mechanical site preparation.

It appears that oak regeneration is at a stage where the final shelterwood removal harvest could be set up any time in the next year or 2.

This would give oak regeneration another 1 to 3 growing seasons before the actual harvest would take place. Managers should be able to maintain anywhere from a fair to good oak component for all units. A commitment to at least 1 more crop tree release and possibly 1 more bud-capping browse protection action for the oak regeneration within the next 2 to 4 years will be critical to achieving and maintain those levels of oak component.

Table 2023-1: October 2023 Red oak regeneration summary by height class and treatment site

Site | Treatment | Height class | Red oak stems/ac. | Stocking (%) |

|

1 | Shelterwood harvest; no understory control; nat. regen only) | 0-1 feet

| 1,771

| 75% | |

1-4 feet | 687 | 58% | |||

2 | Shelterwood harvest; no understory control; nat. regen only) | ||||

4+ feet | 208 | 29% | |||

3 | Shelterwood harvest; herbicide and mechanical site prep; nat. regen only | 0-1 feet | 2,417 | 25% | |

1-4 feet | 333 | 50% | |||

4+ feet | 42 | 8% | |||

4 | Shelterwood harvest; herbicide site prep; planted oak seedlings | 0-1 feet | 2,333 | 75% | |

1-4 feet | 417 | 58% | |||

4+ feet | 167 | 25% | |||

5 | Shelterwood harvest; 2 Rx burns; planted oak seedlings | 0-1 feet | 4,208 | 100% | |

1-4 feet | 1,458 | 75% | |||

4+ feet | 333 | 50% | |||

6 | Shelterwood harvest; 2 Rx burns; nat. regen only | 0-1 feet | 5,895 | 96% | |

1-4 feet | 958 | 58% | |||

7 | Shelterwood harvest; 2 Rx burns; nat. regen only | ||||

4+ feet | 250 | 28% |

NOTE: We analyzed sites 1 & 2 together, and sites 6 & 7 together, since as of 2023 treatment for sites 1 & 2 has been the same, and sites 6 & 7 have also been treated the same. Any treatment differences between units 1 & 2 and 6 & 7 are planned for the future.

Table 2023-2: October 2023 trees/acre and stocking for regeneration > 1 foot in height by species for 7 treatment sites

| Site 1 Nat. regen/no understory control | Site 2 Nat. regen/no understory control | Site 3 Herbicide & mech. site prep, natural regen. | Site 4 Herbicide site prep., planted oak and natural regen. | Site 5 Rx burn, planted oak and natural regen. | Site 6 Rx burn, natural regen. only | Site 7 Rx burn, natural regen. only | |||

Crop Species | Trees/ Ac. | Stock % | Trees/ Ac. | Stock % | Trees/ Ac. | Stock % | Trees/ Ac. | Stock % | Trees/ Ac. | Stock % |

Red Oak | 895 | 67% | 375 | 50% | 584 | 75% | 1,791 | 83% | 1208 | 63% |

Paper Birch | 542 | 34% | 1,167 | 66% | 125 | 16% | 0 | 0% | 21 | 4% |

Sugar Maple | 2,979 | 96% | 292 | 33% | 1,417 | 83% | 1,292 | 100% | 1,942 | 75% |

Red Maple | 771 | 50% | 1,458 | 66% | 1,833 | 92% | 798 | 50% | 395 | 34% |

Aspen | 541 | 46% | 42 | 8% | 209 | 8% | 42 | 8% | 208 | 21% |

Basswood | 41 | 4% | 42 | 8% | 42 | 8% | 42 | 8% | 41.5 | 4% |

Ash | 1,146 | 71% | 708 | 42% | 916 | 66% | 1,208 | 75% | 812 | 58% |

Black Cherry | 21 | 4% | 42 | 8% | 0 | 0% | 0 | 0% | 0 | 0% |

Tamarack | 0 | 0% | 209 | 17% | 292 | 41% | 0 | 0% | 0 | 0% |

B. Hickory | 62 | 8% | 0 | 0% | 0 | 0% | 42 | 8% | 42 | 8% |

Ironwood | 271 | 21% | 0 | 0% | 166 | 25% | 83 | 8% | 0 | 0% |

White Pine | 42 | 8% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% |

Bur Oak | 21 | 4% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% |

Willow | 0 | 0% | 42 | 8% | 0 | 0% | 250 | 25% | 0 | 0% |

Boxelder | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 21 | 4% |

Total | 7,332 |

| 4,377 |

| 5,584 |

| 3,757 |

| 4,690 |

|

NOTE: We analyzed sites 1 & 2 together, and sites 6 & 7 together, since as of 2023 treatment for sites 1 & 2 has been the same, and sites 6 & 7 have also been treated the same. Any treatment differences between units 1 & 2 and 6 & 7 are planned for the future.

Plans for future treatments

Mechanical release of oak seedlings from competing vegetation and oak stump sprout thinning is planned for all seven sites during the fall of 2022. This work is needed to enable adequate numbers of oak to recruit into larger size classes and grow above deer browse height and most vegetative competition before they are fully released by a final harvest removal of most of the remaining overstory trees.

The final harvest for the shelterwood was originally planned for 2019. Assessment as of 2021 appears to show that there are not yet enough “free-to-grow” oak stems above 4’ in height for a final harvest on much of the study area. Another regeneration assessment is planned for 2023, after which a decision on timing for the final stage shelterwood harvest will be made. It will be critical to gather the heights, stocking and “free-to-grow” status information for oak.

We will continue to monitor vegetation, rare animal populations, and other habitat metrics as staff and funding resources are available.

Costs and economic considerations

One of the questions we wanted to answer with this study was the cost of each treatment. See Table 6 below, now incorporating subsequent management since the initial treatment. Not surprisingly, sites 1 and 2 (no silvicultural treatment other than initial harvest) had the lowest cost ($139 per acre), and the planted site 4 (herbicide site prep and planting) and 5 (prescribed burn site prep and planting) had the highest costs ($666 and $768 per acre, respectively).

Costs

Table 6: Costs (per acre) by site and treatment type

| Site # & Description | 2014 Herb. | 2014 Rake | 2015 Plant | 2015 Prescribed burn | 2015 Bud cap | 2016 Plant | 2016 Bud cap | 2018 Prescribed burn | 2022 Brushsaw release | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Site 1. 12.7 acres Nat. regen/no understory control | - | - | - | - | - | - | - | - | $139 | $139 |

| Site 2. 12.7 acres Nat. regen/no understory control | - | - | - | - | - | - | - | - | $139 | $139 |

| Site 3. 10.7 acres Herbicide & mech., nat. regen. | $110 | $210 | - | - | - | - | - | - | $139 | $459 |

| Site 4. 11 acres Herbicide, planted & nat. oak regen. | $110 | - | $340 | - | $40 | - | $37 | - | $139 | $666 |

| Site 5. 11.5 acres Prescribed burn, planted & nat. oak regen. | - | - | - | $185 | - | $287 | $37 | $120 | $139 | $768 |

| Site 6. 11.6 acres Prescribed burn, nat. regen. | - | - | - | $185 | - | - | - | $120 | $139 | $444 |

| Site 7. 11.6 acres Prescribed burn, nat. regen. | - | - | - | $185 | - | - | - | $120 | $139 | $444 |

Revenue

2013 timber sale on 105.2 acres: $25,999.20 ($ 247/acre - 2010 dollars)

Total: $25,999.20 ($ 247/acre 2010 dollars)

*Note: There will be additional timber sale revenue for the final harvest in 2024 or later.

Other notes

We gratefully acknowledge the assistance from members of the initial Adaptive Forest Management Project team for this study:

Original Team Members: Erica Hoaglund (Regional Non-game Wildlife Specialist, Ecological Resources), John Korzeniowski (Area Forest Supervisor, Forestry – Retired in 2022), Michelle Martin (Regional ECS Specialist, Forestry), Jean Mouelle (Regional Silviculturist, Forestry – Retired in 2021), Steve Piepgras (Area Wildlife Supervisor, Fish and Wildlife), Hannah Texler (Regional Plant Ecologist, Ecological Resources), Peter Willis (Program Forester, Forestry).

Local Forestry Consultants: Jeff Wilder (Field Forester) & Mark Anderson (Forestry Technician).

We are also grateful for the review and editing assistance of MNDNR Silviculture Program Coordinator Mike Reinikainen, Mille Lacs Wildlife Management Area Manager Steve Piepgrass and Region 3 Nongame Wildlife Specialist Erica Hoagland.

This case study was developed with support from the United States Department of Agriculture's National Institute for Food and Agriculture, Renewable Resources Extension Act. Project #2021-46401-35956, principal investigator Eli Sagor, University of Minnesota.

Climate Adaptation Considerations

Establishing a diversity of species that are a good ecological fit is an important climate change strategy. The data in Table 2 shows that as of 2021, all treatment sites are well on the way to becoming diverse hardwood stands containing species that are good to excellent crop tree species for the MHc36 plant community. The main species gained by this work was oak – most of the others will become established and recruit to larger size classes easily, without silvicultural assistance.

Establishing a good component of oaks in the stands is a good way to provide some diversity, with other species that are likely to do well in what are thought to be the most likely climate change scenarios. See Figure 11 for a breakdown by species.

Table 7: Species habitat response to climate change in MHc36 plant community.

Tree Type | Response to warmer climate | Response to wetter climate |

Northern red oak | stable | stable |

Sugar maple | stable | stable |

Basswood | stable | stable |

Red maple | slight decrease | stable |

Paper birch | significant decrease | stable |

Aspen | Significant decrease | stable |

Summary / lessons learned / additional thoughts

2023 Update:

As of 2023, all units are on the way to becoming healthy central or northern hardwood stands, with anywhere from a fair to good oak component.

The 2 prescribed burns site preparation treatment (sites 5, 6 and 7) appears to have done the best job of facilitating oak regeneration establishment and recruitment above 1 foot tall so far. However, prescribed burning did not control competing stems of competing sugar maple nearly as well as herbicide and mechanical site prep.

Costs per treatment vary when looking at establishment of red oak over 1 foot in height. The no control sites 1 and 2, and double prescribed burn sites 6, and 7 with natural regeneration were the least expensive per red oak seedling established over 1 foot in height. The most expensive treatment was site prep including rock raking and broadcast herbicide with natural regeneration. This analysis should be revisited after overwood is removed.

As of 2023, it appears that oak regeneration is at a stage where the final shelterwood removal harvest could be set up any time in the next year or 2.

2021:

As of 2021, it appears that there is not yet sufficient advance oak regeneration of adequate size to proceed with a final shelterwood harvest

From the data we have, and observations while collecting it, we feel there is not yet adequate advance oak regeneration of adequate size on any of the sites to support a final harvest decision.

Which treatments have worked best to produce “free-to-grow” advance oak regeneration?

A major question we wanted to answer with this study was which treatment(s) worked best to produce advance oak regeneration of adequate size (4’ high plus) and stocking (60% plus) to ensure a desired oak component in the future stand?

Stay tuned, because it is too early to tell for sure yet. All units had 100% stocking for red oak seedlings, using our 1/100th acre plots. However, the large majority of the seedlings are still quite small.

See Table 2. So far, sites 1 and 2 (natural regeneration, no understory treatment), 3 (herbicide & mechanical site prep, natural regeneration) and 4 (herbicide site prep and planting) have all produced good distribution of more than adequate numbers of total oak seedlings per acre and far more importantly, the highest average heights. Sites 5 (prescribed burn, natural and planted regeneration), 6 and 7 (prescribed burn, natural regeneration) have produced good distribution of more than adequate numbers of oak seedlings, but with the lowest average heights.

NOTE: A similar study showed oak regeneration success in a MHc36 NPC with treatment not exactly the same, but most similar to site 3 (herbicide & mechanical site prep with natural regeneration) and site 4 (herbicide site prep with planted and natural oak regeneration). See link to that study: “Vegetation response 30 years after initiating a two-step oak shelterwood in central mesic hardwoods (MN DNR)”.

The lowest cost treatments were those with natural regeneration and no additional site prep treatments (sites 1 & 2). Highest cost were those units with planting and various types of site preparation (sites 4 & 5). Natural regeneration with various site preparation options were in between (sites 3, 6 &7). See Table 6.

Data collection

We have learned two valuable lessons so far on the data we need, and how best to collect it:

- Sample size: We may not have taken an adequate number of regeneration sample plots to accurately capture the number and stocking of those stems in our 2017, 2018 and 2021 sampling. To address this issue, we plan to expand sample size, and also separate oak seedlings into two height and condition categories (those below 4’ in height, and those above 4’ and “free-to-grow”) for the 2023 regeneration assessment.

- Counting number of stems in sprout clumps: We counted all sprouts in these young clumps during data collection, which tends to skew the regeneration numbers away from what we think would give the best picture of stand condition.

To address this issue for calculating stems per acre and average heights for the 2021 data, we counted multiple sprouts on each plot as 2 stems.

During future regeneration surveys, we will tally young sprout clumps as 2 stems, even if there are more sprouts in the clump. We think this adjustment will give us the best picture of stand condition.